Client: Enable sample part

Part description: Topology optimized structural node, 2kg weight, stainless steel 316

Production method: Additive Casting (Fine Process)

Industry application: N/A

PROJECT

Do you want to break free?

Complex parts don’t have to be expensive

Complexity of parts is no longer a limiting factor for the design of metal parts

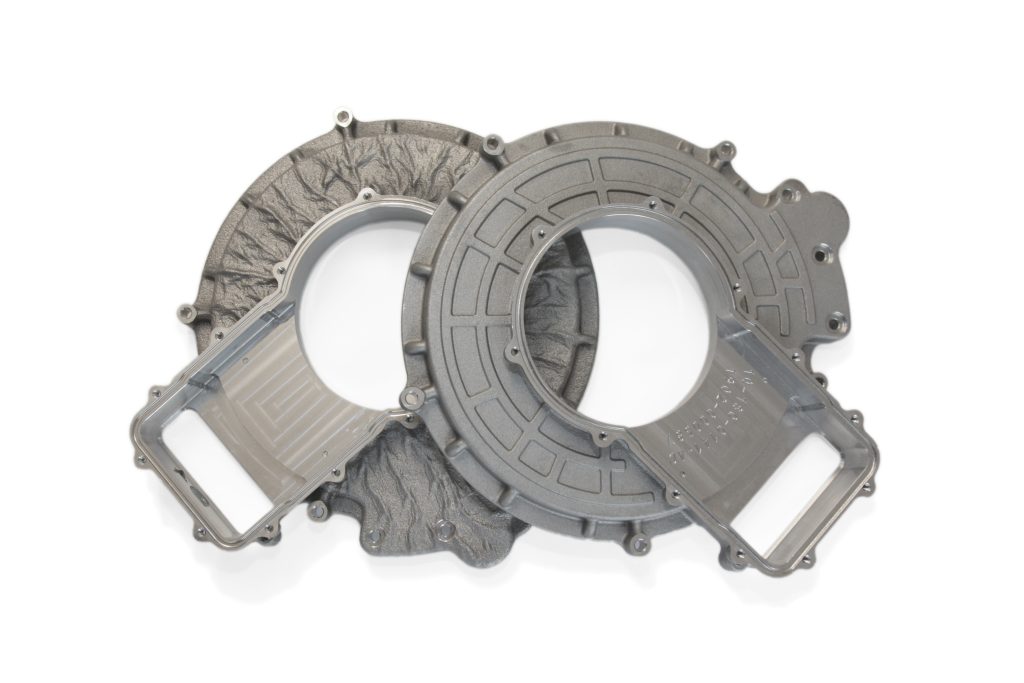

If this part seems a little ‘outlandish’ to you, you are not alone. We are used to metal parts of simple form factors that are easily cast for production volumes of millions of pieces. But not any more. This part combines a series of organic structures, curves, cavities and turns into only one additive cast part – a topology optimized structural node.

Whilst we are more used to seeing structural nodes like the below example, additive manufacturing is giving us a way to break free from the norm. This example consists of numerous parts that need to be manufactured individually and then put together, resulting in high production cost and room for error during assembly. Such designs also tend to be heavy, adding to the weight to the assembly and therefore increases the loads on the structure. By optimising the node to remove material where it is not needed, the engineer can reduce the loads on the structure and save further costs in manufacture.

Additive manufacturing has opened up endless possibilities for designers and engineers to create more complex parts that are optimized for their application and manufactured in the most efficient way possible. And not just for plastic parts, but metal parts, too.

This very cool looking topology optimized structural node has been produced with Additive Casting in our fine detail process, during which a binder is printed on a bed of polymer and bonds the polymer to create the casting pattern. The part is then cast in Stainless Steel 316.

This is a prime example of what becomes possible when manufacturing metal parts with Additive Casting. Complex parts can be produced in more than 130 metals in the Additive Casting process, which is one of the key differentiators to the direct 3D metal printing methods. And parts as complex as this one, would be impossible to produce with traditional manufacturing methods. This leaves a distinct market application for Additive Casting for any part that is:

- Too complex to be produced with traditional manufacturing

- Too large for direct 3D metal printing

- Designed in a material not available for direct 3D metal printing

- Designed for certain material properties not achievable by direct 3D metal printing

To find out more about Additive Casting please contact the Enable team at office@enable.parts.

About Enable

Founded in 2019, Enable is a UK based business that specialises in additive manufacturing, including the manufacturing of moulds for metal casting to produce high quality metal production parts without the limitations of traditional tooling. This method is called Additive Casting and bridges the gap between direct 3D metal printing and traditional metal casting. For more information visit www.enable.parts.

For more information, please contact our office:

+44 (0) 3333 05 09 04

office@enable.parts