Project summary

- Client: Steven Goguelin, Gen3D

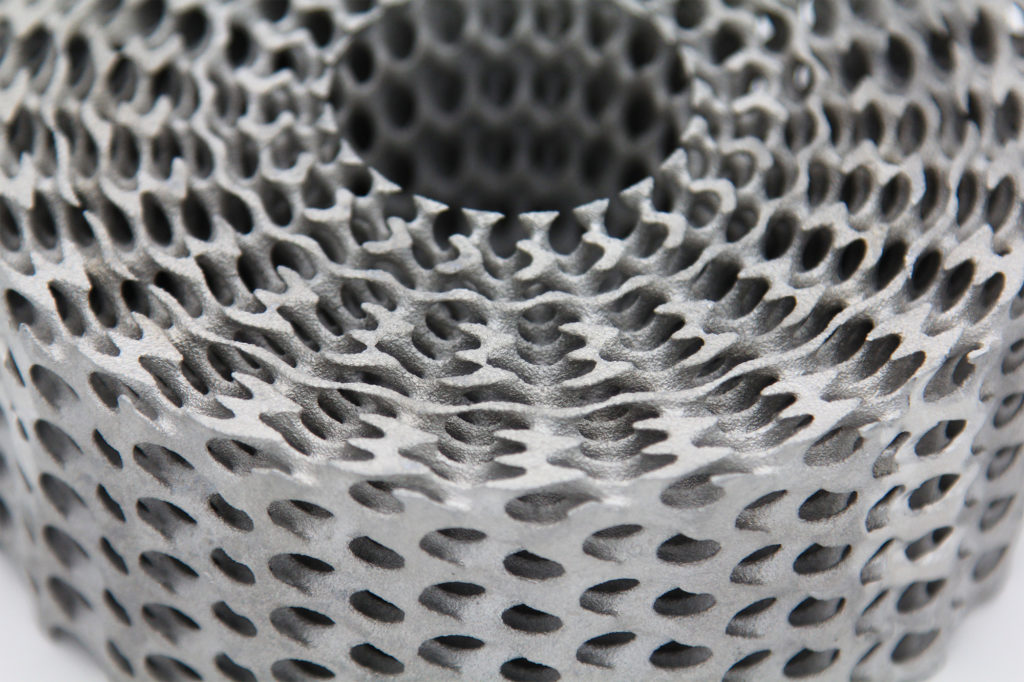

- Part description: Lattice structure for filter, heat exchanger or catalyst converter applications, ø170mm x (H) 70mm, cast aluminium

- Production method: Additive Casting® – Investment casting for ultra-fine detail

- Industry application: Transport, construction, industry

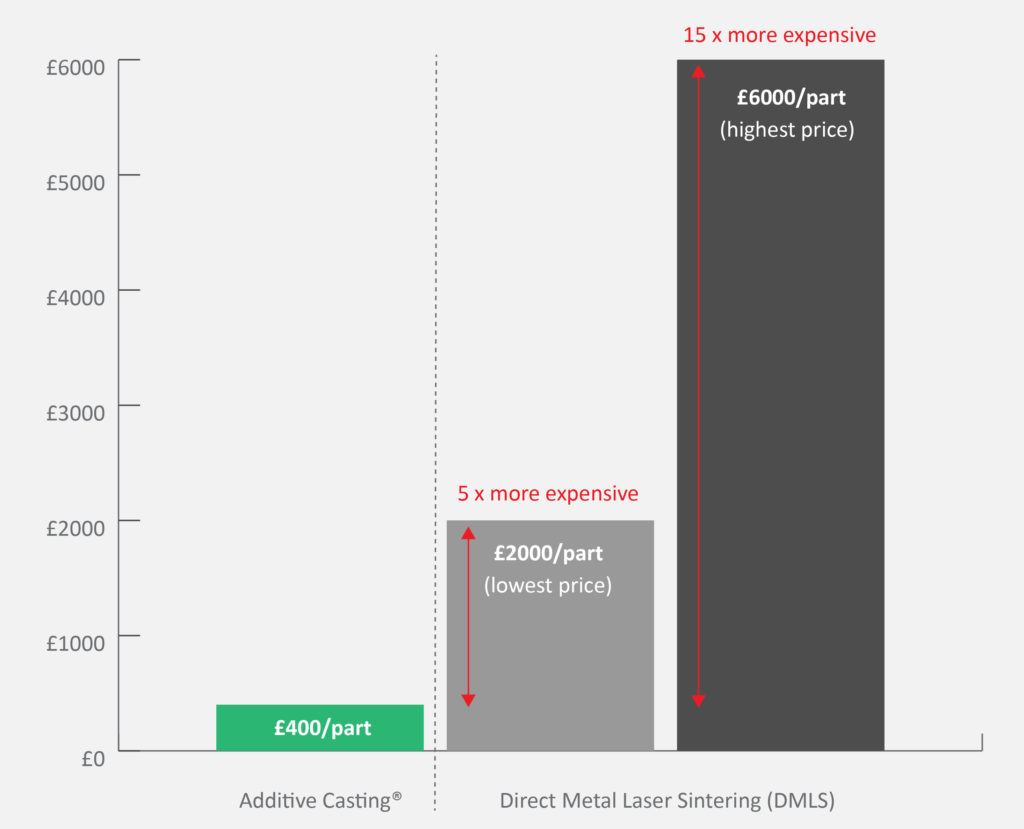

How Additive Casting® enables 80% cost saving compared to DMLS

Traditional metal casting has been around for centuries and has, over time, evolved to be the predominant production method for metal parts. Benefits of metal casting include scalability, the ability to cast a wide selection of metals and cost competitiveness. On the other hand, traditional casting requires expensive investment in tooling and is very limited when it comes to part complexity. Until now.

In autumn 2020, Enable collaborated with Gen3D on the production of a highly complex lattice structure for filter, heat exchanger or catalyst converter applications. This part was to be produced using Enable’s Additive Casting process, a hybrid process combining the benefits of additive manufacturing and traditional casting, making un-castable parts castable.

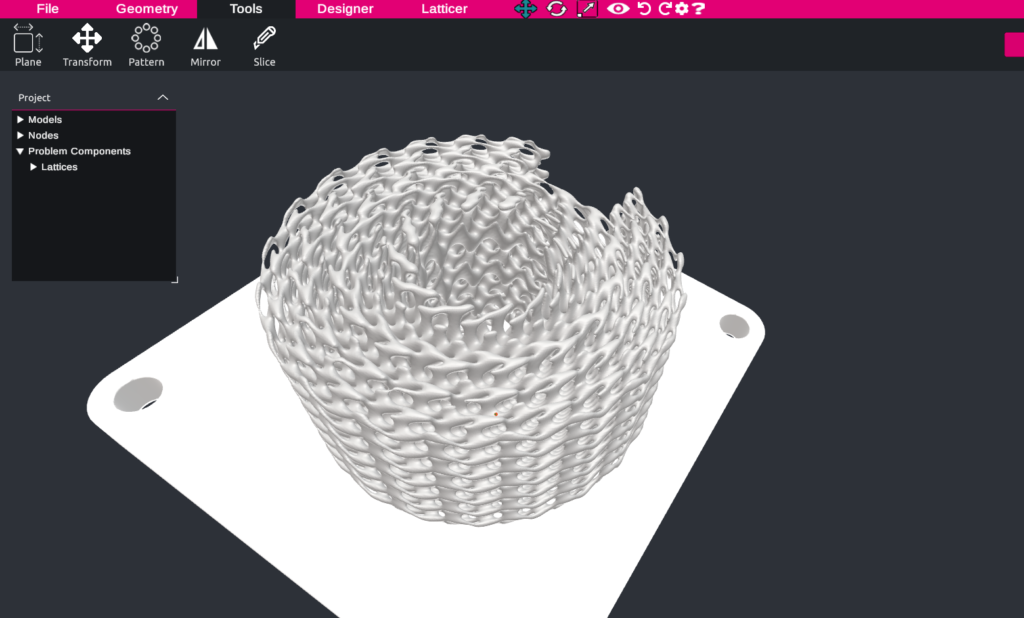

UK based Gen3D specialises in the design of lattice structures and fluid flow geometry for additive manufacturing and has developed a proprietary software application, allowing engineers to design and optimise complex fluid flow components. This software can reduce part cost and material use by adding complex lightweight structures to standard CAD models. The properties of the lattice structures can then be tailored to the application and production method by grading the cell size and density across multiple axes.

Usually, the team at Gen3D would design lattices for Direct Metal Laser Sintering (DMLS) which allows for wall thicknesses as thin as 1mm and helps to maximise the surface area within the lattice that air or fluid can pass through.

‘This project was very exciting because complex parts like this can now easily be scaled at cost whilst offering great quality and a wide choice of materials.’ Steven Goguelin of Gen3D.

This part, however, was specifically designed for Enable’s Additive Casting process which meant that some design parameters had to change, a task that Gen3D’s software could quickly complete.

‘Our software has built-in manufacturing checks and compensation tools which really helped us to adapt the design parameters to the Additive Casting process, whilst still making sure the part will cast successfully. We were pleased that we could reach a wall thickness of 1.5mm for this cast part, allowing for the design of a perfectly functional lattice structure.’ Steven Goguelin of Gen3D.

To cast this part, Enable chose its ultra-fine investment casting process, ideal to manufacture parts as small as 190mm x 160mm x 160mm and allowing for small enough wall thicknesses to meet the part requirements. In this process, a pattern is printed in polymer that is later used for casting the designated metal, aluminum in this case.

‘Additive Casting is the perfect fusion of benefits from traditional and additive manufacturing. A part like this could have never been produced with traditional metal casting processes and this is where Additive Casting sets new parameters of what is possible when combining casting with 3D printing. We call this Casting 4.0.’ Phil Kilburn, Sales Director at Enable.

Using Additive Casting for a complex part like this lattice structure not only ensures high quality, but it’s also cost competitive. Since this part could not have been produced with traditional manufacturing, the only available manufacturing methods would have been DMLS or Additive Casting. At a unit price of £400 per part for a quantity of 5pcs when produced with Additive Casting compared to anywhere between £2000 to £6000 per part for the same quantity of 5pcs when produced with DMLS*, Additive Casting should be a serious consideration for engineers developing similar parts.

*Pricing for DMLS processes was obtained from publicly available online pricing platforms. Please contact us at office@enable.parts for more details.

About Enable Manufacturing

Enable is bringing a new, innovative manufacturing process to life – Additive Casting. The process uses moulds made via additive manufacturing to cast high-quality production parts from over 130 different metals. It bridges the gap between traditional casting and state-of-the-art manufacturing, offering the volume benefits of casting while increasing possible complexity, cutting lead times and eliminating the need for expensive tooling.

For more information, please contact our office:

+44 (0) 3333 05 09 04

About Gen3D

Gen3D disrupts the way that industry designs optimised components for additive manufacturing. Founded in 2018, by academics at the University of Bath, Gen3D is a UK-based technology company providing innovative design software and consultancy to industries globally. Gen3D’s flexible and real-time approach to design allows engineers to reduce lead-times and lower costs. This makes it ideal for many industry sectors including aerospace, automotive, medical and industrial machinery. Find more information at www.gen3d.com @gen3_d.